Rubber Extrusions

Rubber profiles are shaped into their final form by an extrusion process. Extruded products have a constant cross-section along the entire length of the product.

Characteristics of Extruded Closed Cell Rubber are:

1. The surface of the extruded section has a natural skin that is clean and smooth.

2. It is possible to produce the part in continuous lengths.

3. A great variety of complex and unusual shapes may be produced.

4. Air chambers or hollowed out designs may be utilized, giving the advantage of reduction in weight and cost of material. The design engineer, by properly designing the cross section with maximum air chamber space, can generally achieve considerable advantage in terms of performance and compression deflection.

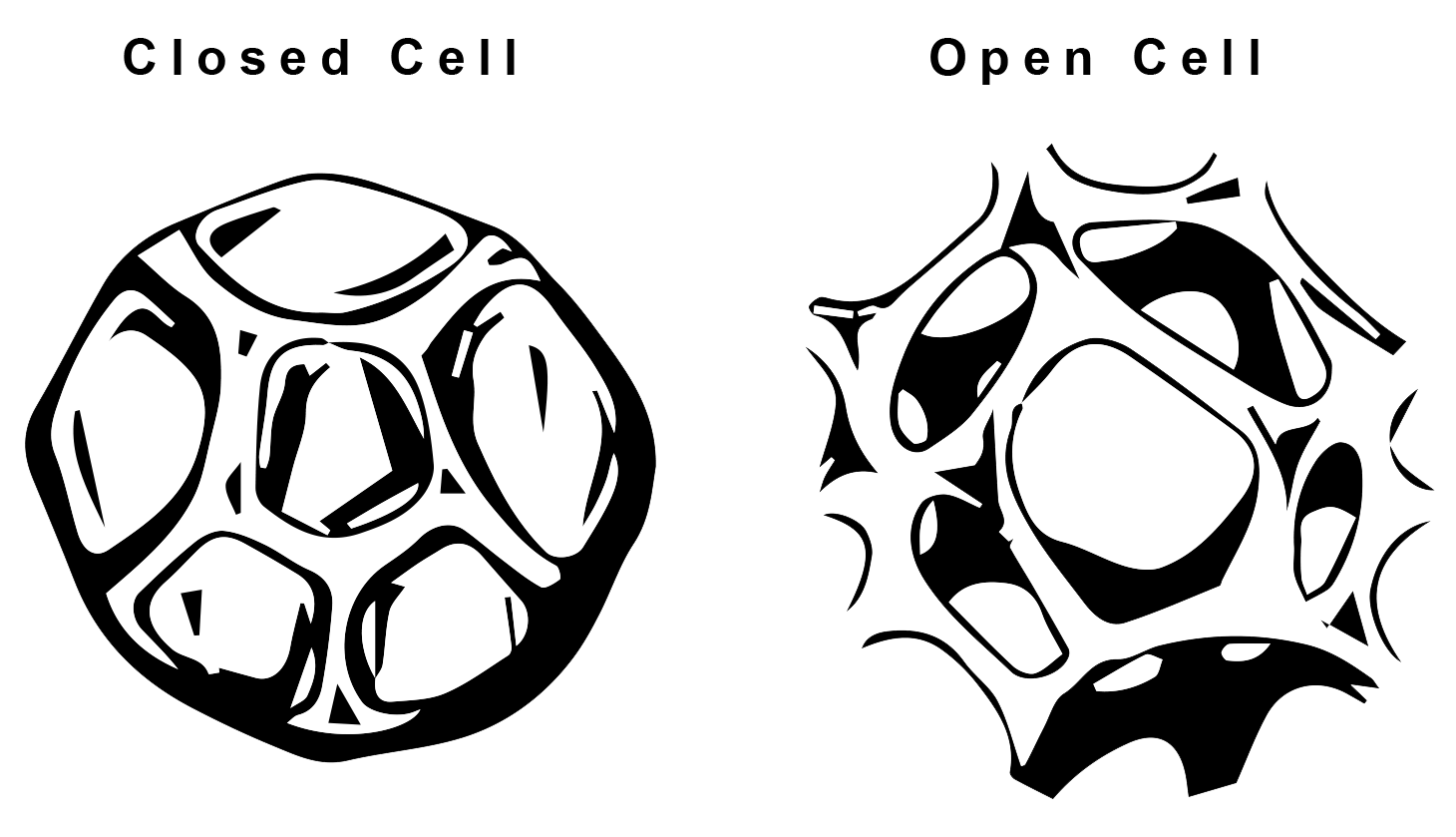

Distinct advantages of closed cell products are their low water absorption characteristics, providing a tight seal and the ability to conform to curves, corners, and varying cross sections without bridging or creasing. This is attributable to the closed cells, which do not collapse, losing air as in open cell sponge, and yet deform (compression set) sufficiently to conform tightly to irregular surfaces.