In many cases, the use of adhesives can eliminate mechanical fastening components (staples, nails or retaining clips), and the inherent problems associated with them, such as cost, weight, and breakage. Double-Coated Film Tapes and Heat Activated Tapes frequently improve productivity during the final assembly process by providing a faster, more efficient way of attaching seals and gaskets to the end product.

To begin the adhesive selection process, it is important to have the answers for several basic questions:

1. To what type of substrate will the adhesive be attached?

2. In what temperature range will the adhesive be expected to perform, and with what chemicals will it come into contact?

3. Will the adhesive come into contact with moisture or sunlight?

4. Will the adhesive be functional after installation?

Double-Coated Film Tapes and Heat Activated Tapes each offer specific benefits depending upon the surfaces to be joined, the strength of the bond required, and environmental factors such as temperature and chemical resistance.

H2 – Acrylic Adhesive

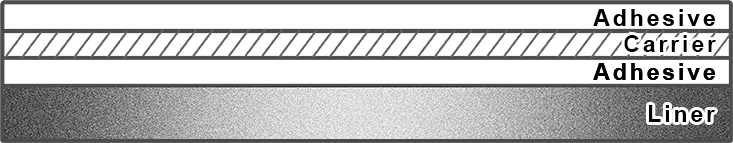

A high tack double coated film adhesive that bonds well to a variety of substrates, including painted or fiberglass surfaces, as well as LSE(low surface energy substrates). It is primarily used in static applications or as a temporary hold before mechanically fastening.

Advantages:

- Good Resistance to Varying Temperatures

- Good Adhesion to Irregular Surface

- Excellent UV Resistance

- Excellent Solvent Resistance

Disadvantages:

- Initial Bond or Tack Strength

(Can take 48 to 72 hours to achieve Maximum Bond)

H3 - Rubber-Based Adhesive

An extremely aggressive double coated film adhesive that adheres well to a broad spectrum of surfaces, including aluminum, bare metals, and stainless steel. It is primarily used in static applications or as a temporary hold before mechanically fastening.

Advantages:

- High Initial Bond to Substrates

- Adheres to a Wide Range of Materials

- Most Economical

Disadvantages:

- Poor UV Resistance

- Poor Solvent Resistance

- Narrower Service Temperature Range

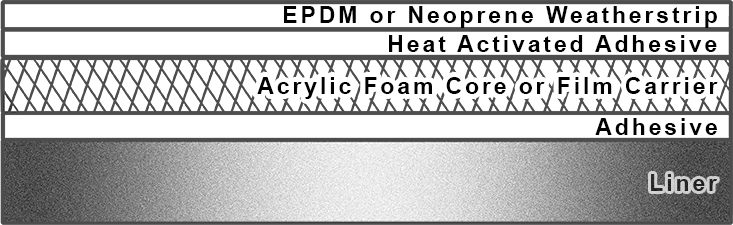

ST / HATS Adhesives

An extremely aggressive, very high strength acrylic foam adhesive that bonds with superior holding power to most surfaces, including automotive paints and metals. It offers the most versatile and robust method for applying seals and is designed to be used in dynamic sealing applications. (The HATS variation is laminated to Neoprene seal profiles). Clean Seal uses high tech heat-laminating equipment to thermally bond the ST and HATS adhesives to the extruded seal. This thermal lamination process ensures a strong, reliable, inseparable bond of the adhesive to the seal profile.

Advantages:

- High Initial Bond

- Excellent UV Resistance

- Excellent Solvent Resistance

- High Performance Adhesive

Disadvantages:

- Higher Cost Product